With the job costing approach, your business completes work on a project basis. At Vantage-CFO Financial Services, we specialize in helping businesses understand and implement effective costing systems that align with their financial goals. Our expertise ensures that your business benefits from accurate costing data, enhancing profitability and financial control. Discover how our financial solutions can help optimize your business today. Process costing applies to more routine and repetitive production processes.

Process Costing in the Digital Age

That amount is either debited to the next department’s WIP account or to finished goods (if this is the last department in the production chain). If you sum the three ending WIP products above, you have the total cost of ending WIP. If you sum the three units completed products above, you have the total cost of units completed and transferred out. This is always the case when there are beginning WIP equivalent units. If there are no beginning WIP units, the two methods operate in exactly the same way. Again, the only difference between the two methods is that stinking beginning process costing WIP.

Step #5 – Allocation of Costs

Material can be introduced in the beginning, in the middle or at the end of the process. The stage at which material is introduced will significantly affect cost per unit of the process. The statement showing physical flow of units will also indicate normal or abnormal loss.

Indirect Costs

Equivalent units are not physical units but they are abstract units used to facilitate calculation of product costs and performance. When no complexity of process costing is involved, process cost determination is a very simple exercise. This standardization of products allows managers to evaluate production. Managers can then look at individual departments to lower production costs, and thereby increase profitability.

- All direct expenses and indirect expenses relating to the product are debited to the process account concerned.

- The classic example of a process costing environment is a petroleum refinery, where it is impossible to track the cost of a specific unit of oil as it moves through the refinery.

- Some overhead cost should go to these units still in WIP, just not a full unit’s worth of overhead costs.

- The flow of goods through production is more evident in Figure 8.2, which depicts Dinosaur Vinyl as a simple factory with three stages of production.

- Those costs represent work done on equivalent units from last period.

Step #2. Calculate equivalent units

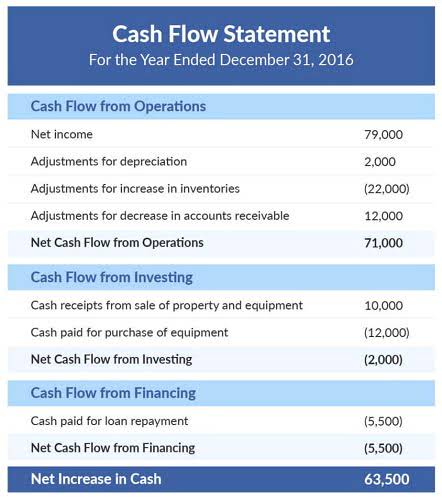

The concept of “equivalent production” is used for assigning cost of process to both finished units and unfinished units. Keeping records of various business expenses and payments is essential to maintaining inventory and ensuring a business can pay its bills and employees. It involved tracking units of inventory, such Liability Accounts as crops and herd animals, and payments received for the units sold. Early economies relied on the bartering system, which required only basic bookkeeping.

- This method simplifies calculations but may not account for the precise flow of costs within the production process.

- Let’s assume, a manufacturing business completed 4,000 products and has another 1,000 units halfway through production, the total costs would be divided by 4,500 units